iNGENUITY MADE

raw materials-

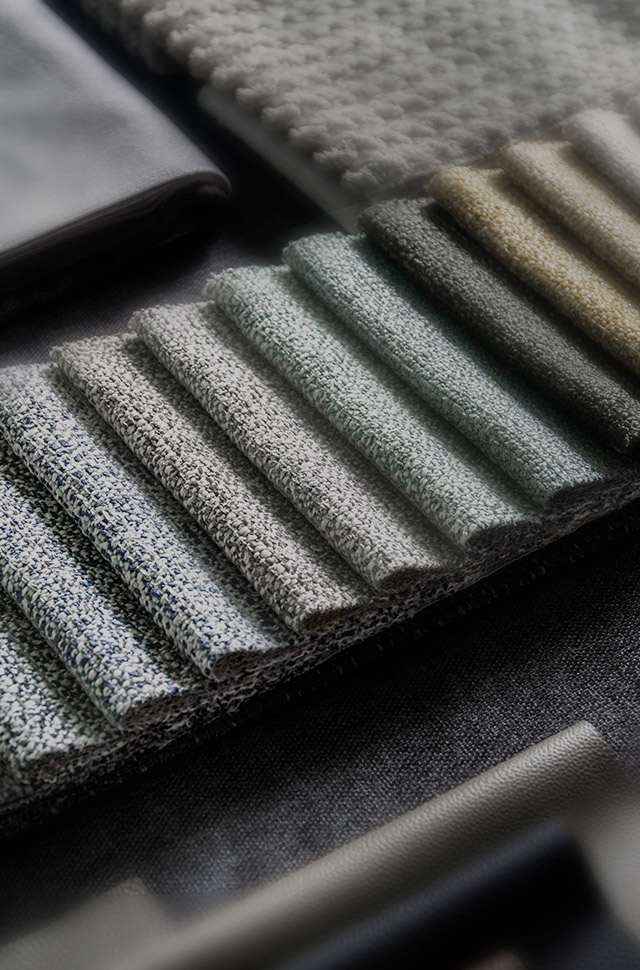

Fabrics

Our fabric has a unique feel. Whether it is natural fabrics or high-tech fabrics, they all have a pleasant touch.

The sofa fabric has passed the SGS pollutant test, color fastness, abrasion resistance test, and the pursuit of environmentally friendly production technology under the high-value appearance. The precise weaving technique composes the fiber structure into a unique fabric texture. The fabric texture is rich in texture and enhances the overall beauty of the product. The fiber structure is neatly arranged and tightly spaced to prevent the entry of moisture. lt is easier to clean and maintain daily,and it can prevent bacteria from becoming moldy. Good fabric breathability and soft and delicate surface make the sitting experience more comfortable and refreshing.Each fabric has its own "identity certificate" , which describes the production information of the fabric in detail, which can be traced and inquired.

*The fabric is numbered by SGS certification :

No. SL518252728196TX

No. SL518252719589TX

No. SL517152227384TX -

Suture Thread

SOFAX HIGH - STRENGTH SEWING THREAD, in line with Oeko-Tex® Standard 100

Ingenious craftsmanship,the pursuit of materials and craftsmanship only reveals the details, and sincere quality can stand the test of time.Our wire is a customized high-compressive-resistance suturing thread , which is characterized by wear resistance and fracture resistance, meticulous and delicate suture, which highlights the details with each stitch. All raw materials comply with Oeko-Tex® Standard 100.

*Oeko-Tex® Standard 100 is a unified textile testing and certification system including all p rocessing levels including textile primary products,intermediate products and final products. -

Spring

Passed 100,000 endurance support stress tests

High-carbon memory steel wire is selected,after double high temperature heat treatment, the spring toughness and secondary rebound effect are stronger,and it is quenched into a beautiful balance of rigidity and flexibility.The pocket spring cushion made of two-way reinforcement with 5 processes of independent spring positioning line technology is very stable, quiet and anti-interference,and plays a vital role in the support and durability of the sofa.

Passed 100000 endurance support stress tests

*The durability test is tested by the Furniture Quality Supervision and Inspection Center, report number:W01713112682 -

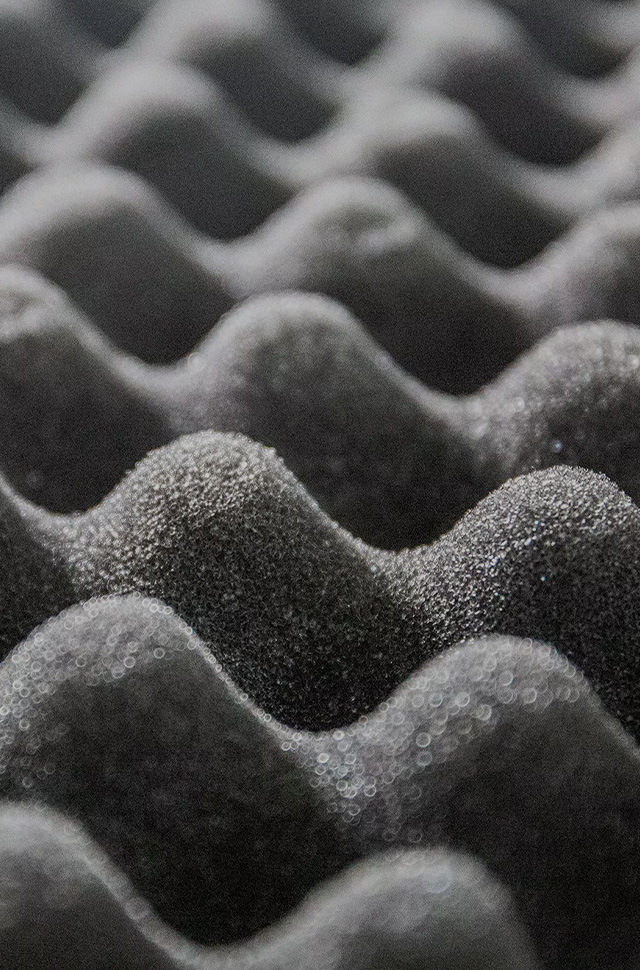

Filler

The R&D department is committed to choosing suitable fillers for each product through the combination of materals. which can adapt to the body curve and improve comfort -

Environmentally Friendly Adhesives

No peculiar smell-healthy resin spray glue, strong initial viscosity, fast speed,impermeable pressure sensitive adhesive, long sticky curing time

High-carbon memory steel wire is selected,after double high temperature heat treatment, the spring toughness and secondary rebound effect are stronger,and it is quenched into a beautiful balance of rigidity and flexibility.The pocket spring cushion made of two-way reinforcement with 5 processes of independent spring positioning line technology is very stable quiet and anti-interference,and plays a vital role in the support and durability of the sofa.

Passed 100000 endurance support stress tests

*The durability test is tested by the Furniture Quality Supervision and Inspection Center, report number: W01713112682 -

Plank

No peculiar smell-healthy resin spray glue, strong initial viscosity, fast speed,impermeable pressure sensitive adhesive, long sticky curing time

The main material comes from poplar wood certified by the EUDR, which has undergone the strict fumigation and disinfection treatment,and has anti-insect and anti-corrosion properties. The veneer grades are formed into LVL boards by hot pressing technology according to the parallel grain group embryos.LVL board can disperse and stagger defects such as scars and cracks of logs thereby greatly enhancing the impact on strength,making it characterized by stable quality,uniform strength and low material variability.The performance of LVL in shock resistance and shock absorption performance is more reliable and firm.

*Formaldehyde emission is lower than the national standard, Certified by BV Certificate Number:BV-COC-126507

*Formaldehyde emission is lower than the national standard, Certified by BV Certificate Number:BV-COC-126507

*FSC certification: The Forest Management Committee certification system is a forest certification system supported by non-governmental environmental protection organizations and trade organizations.Certificate Number:FC-COC-158380